The great explorer of the truth, the master-builder of human happiness no one rejects dislikes avoids pleasure itself because it is pleasure but because know who do not those how to pursue pleasures rationally encounter consequences that are extremely painful desires to obtain.

Read More

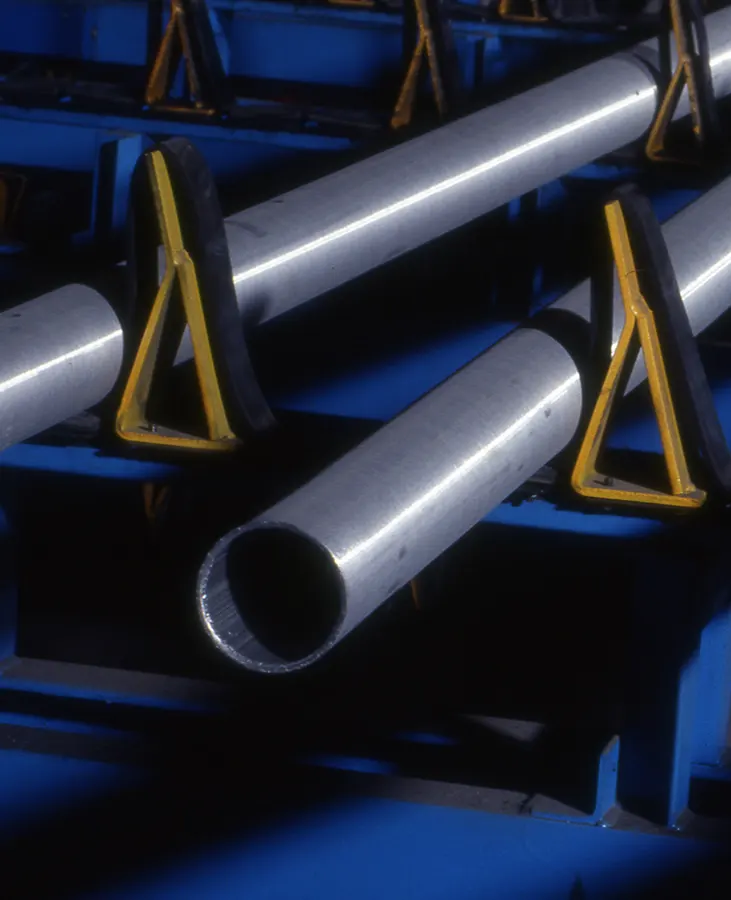

Seamless Pipes & Tubes

As the name implies, a seamless pipe has no seams or welded joints. The strength of a pipe with a seam or that has been welded together is only as strong as the seam or weld-joint. Seamless pipes and tubes have a consistent structure and strength throughout the pipe body since they lack such a seam or connection. Seamless Pipes and Tubes are hence capable of withstanding higher pressure, higher temperature, higher mechanical stress, and corrosive environments. Oil & Gas, Refinery, Chemical, Fertiliser, Power, Automation, Bearing, Mechanical & Structural applications are It will be just a few industries that seamless pipes are widely used in.

We procure seamless pipes and tubes, which are manufactured by heating round steel billets or bars and then stretching the steel over a bullet-shaped piercer. We ensure that the finished goods supplied by us have gone through NDE testing, hydrostatic testing, inspection, and coating, if necessary, and stencilling with the needed standards.

We provide personalised service to each client while maintaining high standards for quality and meeting deadlines. We adhere to a regular control procedure to make sure the quality of the products we supply is top-notch. For improved customer satisfaction, our extensive services guarantee timely delivery of premium seamless pipes and tubes.

Our Seamless Pipes & Tubes’ Product Portfolio:

| S. No. | Product Categories | Dimension Capabilities (OD in Inch) | Wall Thickness (in mm) | Pipe Length (in Mtrs.) (subject to transportation restriction, as applicable) |

Specification Standards & Grades | Application | |

|---|---|---|---|---|---|---|---|

| Min. | Max. | ||||||

| 1 | Seamless Line Pipe | ½” ~ 3½” | 2.00 | 15.24 | 3 to 14 Mtrs. | ~ ASTM A - 53 Gr. A / B / C ~ ASTM A - 106 Gr. A / B / C ~ IS: 1239-1 ~ API 5L - Gr. B; X42; X60Q; X65Q; X70Q / PSL-1/2 NACE MR0103 / MR0175 ~ ISO3183 / EN10208 |

~ Sour, Non-Sour application ~ Flow Line Pipe ~ On-shore & Off- shore Line Pipe ~ Pipeline for combustible fluid |

| 2 | Seamless Boiler Tube | ¼” ~ 3½” | 2.00 | 12.70 | 3 to 14 Mtrs. | ~ ASTM/ASME A/SA-333/4 Gr. 1/3/6 ~ ASTM/ASME A/SA-210 Gr. A1 / C ~ ASTM/ASME A/SA-213 Gr. T11 / T12 / T22 / T1 / T5 / T9 / T91 / T92 / T93 ~ BS3059-1/2 Gr. 320 / 360 / 440 / 620 / 622 ~ EN10216-1/2 P235TR1/2; P265TR1/2; P235GHTC1/2; P265GHTC1/2 ~ EN17175-16Mo3 |

~ Low Temp. service ~ Boiler Equipment application ~ Heat Exchanger application ~ High Temperature application ~ Pressure Vessel application |

| 3 | Seamless Structural Tube | ½” ~ 3½” | 3.00 | 15.24 | 3 to 14 Mtrs. | ~ EN10210-1 (S235JRH to S355J2H) ~ EN 10297-1 (E235, E275, E355) ~ IS 1161 / 3601 - YST 210 / 240 / 310 |

~ Structural Tubes for Construction and Infrastructure |

| 4 | Off-shore Structural | 1” ~ 3½” | 3.00 | 15.24 | 3 to 14 Mtrs. | ~ EN 10225- S335NHHO/S355NLHHO ~ API 5L- X52 (PSL-1/2), X60 (PSL-2) |

~ Off-shore platform application |

| 5 | Seamless Mechanical Tube | ½” ~ 3½” | 3.00 | 15.24 | 3 to 14 Mtrs. | ~ SAE 4130 ~ ASTM A-519 ~ DIN 1629 / ST.52 |

~ Premium quality ~ Superior finish ~ High wear resistant |

| 6 | Seamless Galvanised Tube | ½” ~ 3½” | 2.00 | 12.70 | 3 to 14 Mtrs. | ~ ASTM A-106 / A-53 Gr. A / B / C ~ IS: 1239-1; IS: 1161; IS: 3601 (550 GSM) |

~ For Infrastructure ~ For Refineries ~ For Water pipeline |

| 7 | Seamless Stainless Tube | ½” ~ 3½” | 2.00 | 12.70 | 3 to 14 Mtrs. | ~ ASTM/ASME A/SA - 213; A/SA – 312 ~ TP - 304; TP - 316; TP - 321 |

~ Premium quality ~ Superior finish ~ Corrosion resistant |

| 8 | Bearing Tube | 1” ~ 3½” | 2.00 | 12.70 | 3 to 14 Mtrs. | ~ SAE 52100 | ~ Premium quality ~ Superior finish |